12

May

Cut-Resistant Gloves vs. Chemical-Resistant Gloves: Which Is Right for Your Job?

February 03, 2026

Choosing the wrong safety glove can be as dangerous as wearing none at all. At Qingdao Meiji Labor Products Co., Ltd, we've seen how improper glove selection leads to preventable injuries. This guide compares cut-resistant gloves and chemical-resistant gloves – two fundamentally different protections – to help you match PPE to your workplace hazards.

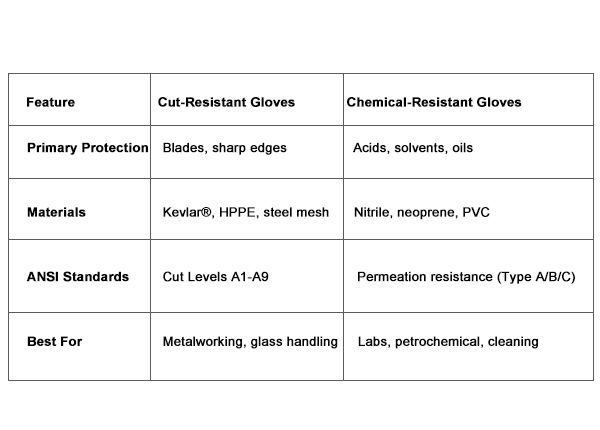

1. Key Differences at a Glance

2. When to Choose Cut-Resistant Gloves

Ideal Work Environments:

◉ Metal fabrication & machining

◉ Automotive repair

◉ Construction (rebar handling)

◉ Food processing (knife work)

3. When Chemical-Resistant Gloves Are Essential

Critical Applications:

◉ Chemical manufacturing

◉ Oil/gas refinery maintenance

◉ Pharmaceutical production

◉ Battery handling

4. Hazard Misidentification Risks

Costly Mistakes We've Observed:

→ Using cut gloves for chemical spills (result: rapid degradation)

→ Wearing chemical gloves near rotating machinery (risk: entanglement)

Qingdao Meiji's Solution:

Our free hazard assessment service identifies:

✓ Primary vs. secondary risks

✓ Material compatibility

✓ Required dexterity levels

5. Hybrid Solutions for Complex Environments

Some jobs require dual protection:

✔ Slaughterhouses: Cut resistance + bloodborne pathogen protection

✔ Waste management: Puncture resistance + chemical splash guard

6. The Qingdao Meiji Selection System

We simplify choices with:

1️⃣ Hazard Matrix Tool (match threats to glove specs)

2️⃣ Size Matching Technology (3D hand scans for perfect fit)

3️⃣ Compliance Cross-Check (automated standard verification)

Conclusion: Protection Is Precise

Like choosing between a helmet and a respirator, cut and chemical gloves serve distinct purposes.

Qingdao Meiji Labor Products Co., Ltd provides:

→ Accurate hazard-specific gloves

→ Scientific testing data

→ Ongoing PPE training

Don't guess – test! Contact our specialists for a free glove compatibility analysis today.

info@meijigloves.com

www.meijigloves.com